Société Fadoul Technibois

Founded in 1981, Société Fadoul Technibois (SFT) is a major player in the construction sector (Buildings & Civil Engineering) in Burkina Faso.

Thanks to the constant effort of its entire team, the company has been able to diversify over the years and has acquired know-how and solid experience in the management of its construction projects.

The 1990s were marked by major construction projects, such as the rehabilitation of the Presidential Palace, the SONAR headquarters, the gear factory in Diébougou for SOFITEX and by major hydraulic works such as the construction of the Niofila and Tourni dams, the drinking water supply of Bobo – Dioulasso as well as numerous civil engineering works such as the Bolmakoté water tower. The 1990s also saw the first contracts executed outside Burkina Faso, such as CRAAE in Abidjan.

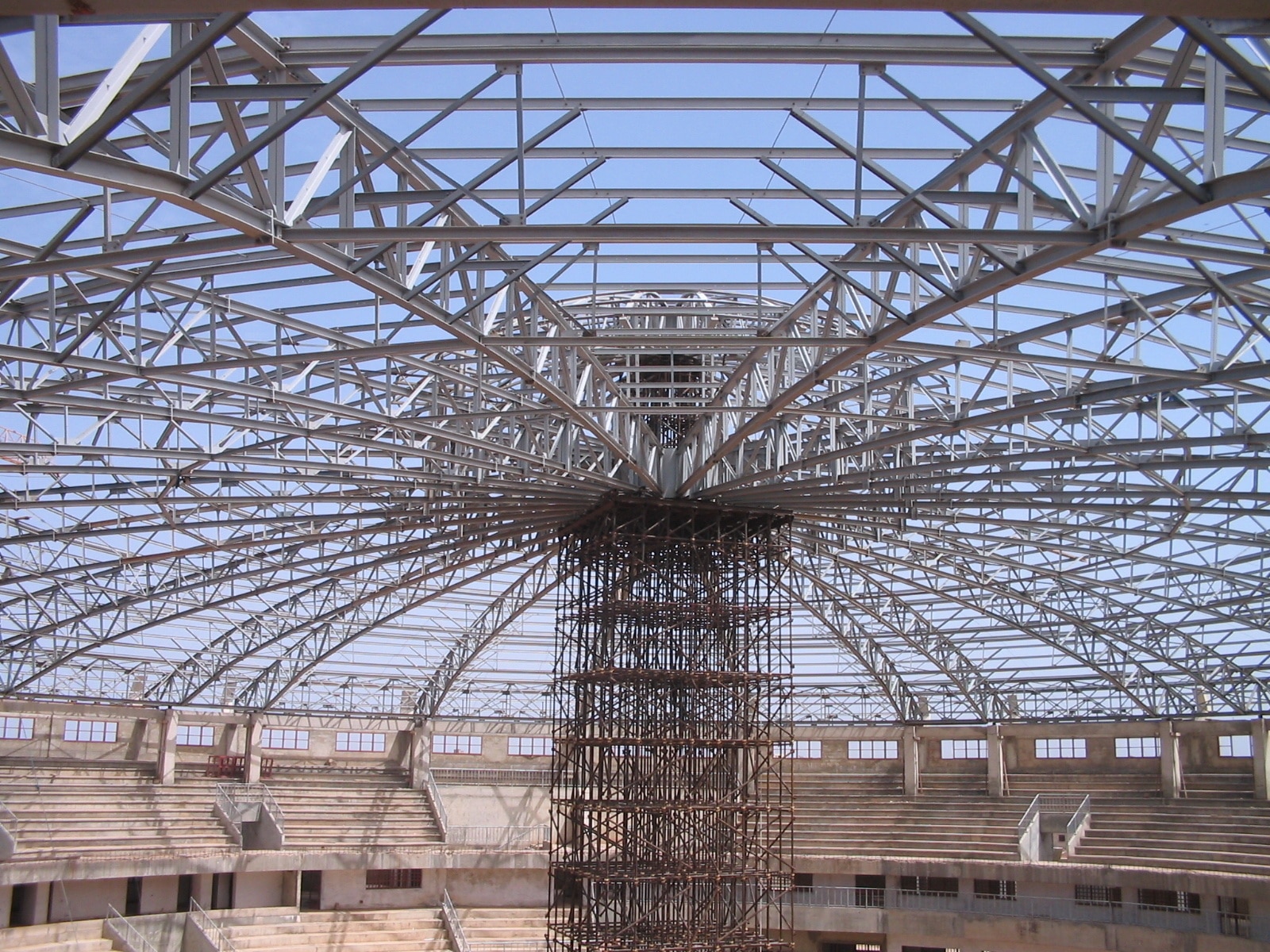

In the 2000s, SFT demonstrated its expertise by building major projects in the hydraulic sector, such as the drinking water supply of Ouagadougou and Fada N’gourma, and in the construction sector, such as the ENEP in Gaoua, the new Presidency, and the Palais des sports in Ouagadougou.

The 2nd millennium was also the beginning of the company’s development in the road sector with the maintenance of dirt roads, the completion of asphalting work on the Ouaga-Léo, Ouaga-Kongoussi road and other road works. The company also demonstrated its ability to carry out the most complex works such as the West Ouagadougou Gate Interchange and the three Kara bridges in Togo. During these years, SFT continued to export its know-how by executing contracts such as the 2002 CAN works (asphalt roads and gutters in Bamako), the development of roads in San Pedro (Ivory Coast),…etc.

SFT’s achievements can be counted by the hundreds today and have consolidated SFT’s reputation as a company capable of meeting challenges requiring extensive technical expertise and a high level of competency.

Our most valuable assets are our human resources resources, which are able to adapt to the company’s various areas of activity, as well as our equipment, which is constantly being renewed.

SFT is attentive to its customers, who are the true reflection of its brand image.

SFT is committed to the development of Burkina Faso and its neighbouring countries by actively participating in the economy and the development of wealth in order to build the future together.

SFT’s vision

Fadoul Technibois is a construction company mainly active in four sectors: Earthworks-Roads, Engineering Works, Hydraulic Works and Buildings.

Our motto is a few words:

Driven by a passion for building, SFT has established itself as one of the most important companies in the sector through the quality and diversity of its achievements.

It strives to develop trustworthy relationships with its clients.

SFT is part of the Fadoul Africa group, which gives it multiple advantages in terms of synergy, logistical support and expertise in the specific data of each market.

The Fadoul Africa Group, a multi-disciplinary group with more than 100 companies, has firmly established itself in most West and Central African countries for more than 35 years thanks to its human, logistical and financial resources, which enable it to be very responsive to the needs of its clients.

Our activities

Our resources

Our projects

Contact Us!

Rue Fadoul

Zone Industrielle de Gounghin

01 BP 218 Ouagadougou 01

Tel : 25 42 42 42

Mail : info@groupefadoul.com